A Real Head Case

- Paul Wegweiser

- Oct 15, 2020

- 6 min read

I've been driving 2002s for over 35 years. There are things that fail...and things that are nearly bullet-proof and never fail... until they too fail. Head gaskets seem to be in the later group for me lately... **shrugs shoulders**... but there's no mystery or randomness to mechanical failures. There's ALWAYS a cause.

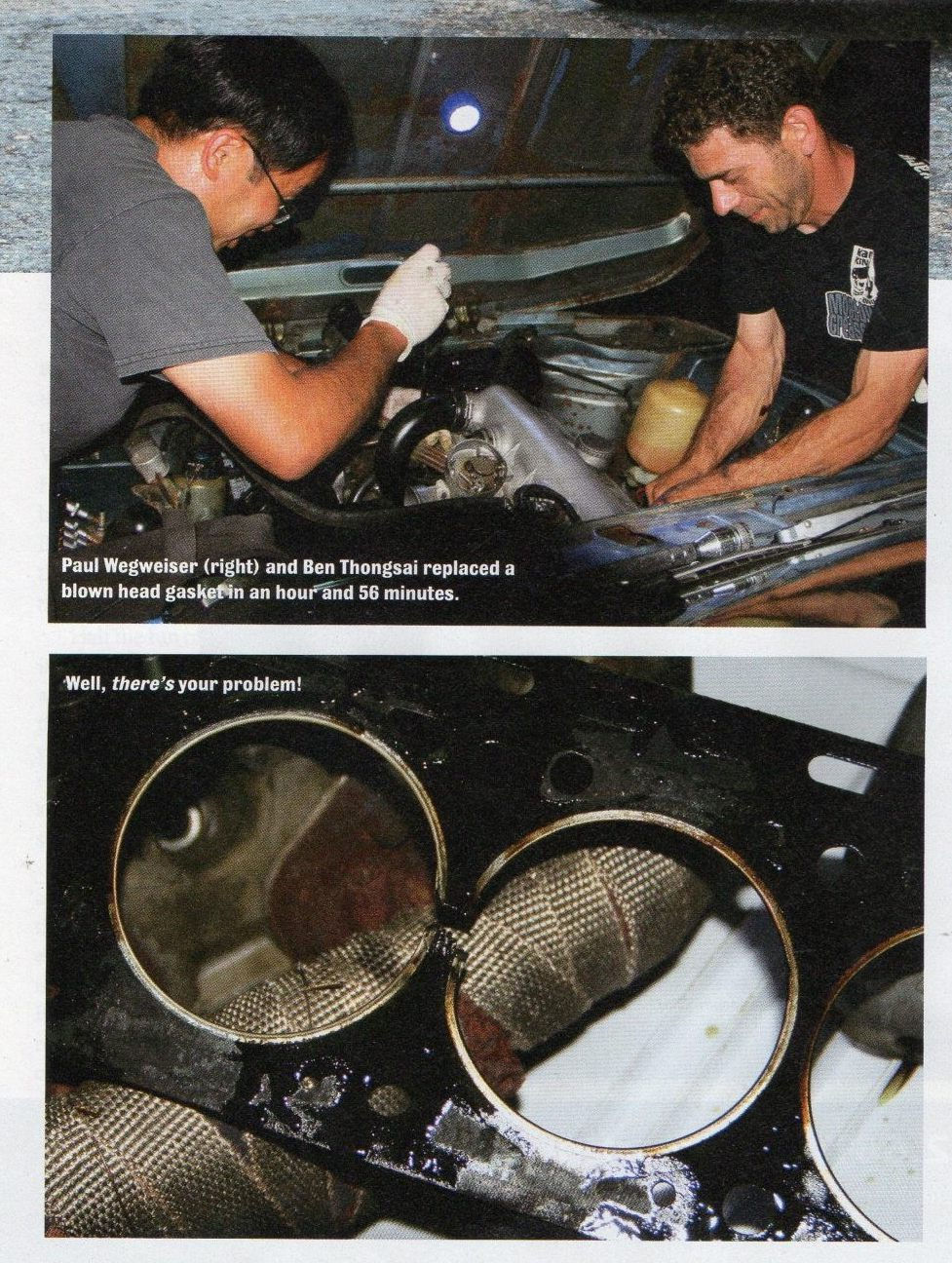

A few years ago, I had a head gasket fail on my 72 tii while 7 hours from home in North Carolina, the night-time outdoor repair of which has become the stuff of both myth and legend. We replaced it (by flashlight) in the parking lot of a hotel in 120 minutes. I had superb assistance from one of the finest BMW techs in the USA. (The elusive and brilliant Ben T, whose brain functions on a higher level than the rest of us casual morons.) The cause of that head gasket failure? A combination of age (that particular car sat untouched for 15 years before I cleaned it up and began driving it - and the head gasket was who-knows-years old) and some ignition timing issues (ignition distributor started coming apart)...the thing finally threw its hands up in the air and said "I GIVE UP" as we were on our way to grab award winning BBQ. I think I still owe Ben dinner.

Think I'd learned my lesson?

Of course not.

Because I am dumb and stubborn and I like a challenge apparently.

Fast forward to October of 2020:

I've been driving the WHEELS off my 1969 barn-find 2002 since dragging it from a shed in June of 2019. The motor was seized when I got it, and after knocking things loose with gentle use of mallets and wooden blocks, I did a quick and dirty hone of the cylinders, establishing that they were (more or less) within standard bore specification, and re-sealed the engine while installing fresh timing chain components and bearings. This was an experiment to see if I could even get the car on the road again...using a lot of new and existing parts from my garage... a budget build from leftover bits accumulated through decades of 2002 ownership and repair.

And it actually ran.

In fact it ran so well, things evolved on it....from single barrel Solex to two-barrel Weber....and eventually a set of 40mm side draft Weber DCOEs. For months, I've been saying that if I had known this engine would run SO DAMN WELL, I would have done a better job of assembling it. As it was, I simply plopped the old cylinder head back on the "slightly freshened" bottom end and started scorching the highways with it. I barely even degreased the original head before reinstalling it. "Real" engine builders will now scold me whilst rolling their eyes, I know. I'm a fairly competent engine "assembler".... but I lack the finesse and math skills to attain true engine "builder" status. There's a difference.... a BIG one.

I'd spent the last 12 months happily bombing EVERYWHERE in this car... and most recently, a few (three) round trip high speed trips from Pittsburgh PA to Chicago IL where I'm helping out on a special project with some other insane 2002 goons. Last weekend was my fourth trip out there....a drive I've been able to complete in 6 hours and 15 minutes on occasion (after signing a contract with the evil forces of the universe).... but not this time.

About 30 minutes after a triple digit speed run (which lasted about an hour through the flats of Ohio, alongside a modern VW GTI exchanging "thumbs up",) I suddenly hear clattery sounds from the engine bouncing off the concrete barriers of the interstate. I had only a slight loss of power, but my immediate concern was ignition timing....and I was sort-of almost half correct. I grabbed the nearest exit (about 2 miles later) and found that the car wouldn't hold an idle.

And it was getting worse.

I stood next to the toll booth and inspected ignition components....because we all know that 90% of carb problems are actually ignition problems. I was immediately struck by the looseness of the Petronix magnetic ring on the cam of the distributor. I could easily rotate it a few degrees back and forth, and it appeared to be stripped out, somehow. Ah Ha! Inaccurate timing! I removed the electronic ignition stuff and re-installed points and an old condenser from the tool kit in my trunk.... figuring my work was finished and I'd have smooth sailing for the rest of the weekend. I had brought a timing light with me (who does that, right?) and re-set the timing "just right".

NOPE.

Car ran worse and worse... So I limped it to the nearest parking lot I could find about a mile from the exit ramp, just south of Toledo Ohio. Conveniently parked my wounded rig between an Auto Parts store and a Harbor Freight store, I determined that cylinder #2 was just along for the ride...and #1 wasn't much better. Having side draft carbs can be handy - because you can use their independence to isolate a problem... so I checked fuel delivery passages for blockage... checked float level for presence of fuel and needle valve function. All looked OK. Having experienced head gasket failure once before, I ponied up $35 for a compression tester....and soon realized my boat was sunk. ZERO compression in cylinders one and two. Part of me was relieved, as TWO cylinders failing seemed more like head gasket failure and less like a single melted piston problem. "OK" I thought... between these two stores, if I can score a head gasket, I can fix it right here and now, and then continue to Chicago - 4 hours away.

It turns out that contrary to what I had been told, Toledo Ohio does not have an orchard full of M10 head gasket trees. *sigh*

My options were:

A) Rent a car and pick up a head gasket from my friends in Chicago - then fix the car on my way home, after a weekend of other tomfoolery.

B) Have the car towed home to PA and give up. NEVER!

C) Limp the car on 2 cylinders for 4 more hours, risking a complete breakdown in rush hour Chicago traffic. Oh HELL NO.

D) Rent a U Haul box truck and trailer... and continue onward to Chicago.

I'm not sure which option translates to "...coming home WITH your shield...or ON it" as the Greeks were fond of saying... but I took option D. There was vanity and a reputation at stake!

I was lucky enough to limp it the 1.6 miles to a Toledo U Haul place that had everything I needed. The car had just enough engine remaining to drive it on to the trailer myself.... **WHEW!**

And then 4 hours of 74 mph (electronically limited) drudgery ensued. I arrived in Chicago after 12 hours on the road, at 7:30 local time. Completely. Whooped!

The next day, the council of elders gathered at Ben's shop in Chicago helped me clean and disassemble the requisite portions of the engine. it was soon determined that the head needed to be resurfaced, as parts of it were no longer perfectly flat....and that I was about to lose cylinder 3 to the same fate that met cylinders 1 and 2. My host found a machine shop willing to resurface the head on a moment's notice, and we had a shiny, flat surface ready for reinstallation 90 minutes later. THAT was a minor miracle!

Reinstalled the head, set the timing, tweaked the idle mixtures, and it all seemed good...but sometimes, when you get too familiar with something, you miss the details. "Familiarity Breeds Contempt", right? It's so true. While discussing ignition timing flukes, I mentioned that I had removed the vacuum advance unit from this particular "spare" junky distributor, as I had no need for it, and wanted to clean up the engine bay from excess "stuff". What I neglected to do, was to lock the rotating plate it was once attached to. The plate did not move easily, so I figured it wouldn't affect timing.... but when you travel at 5000 rpm for 5-6 hours at a time... stuff vibrates....and stuff moves....and stuff wears out. The council of elders had a good laugh at my expense, as they explained all of this to me. I'm smart and know a bunch of stuff about 2002s... but I learn something new every day. Even if it's painful and makes me the target of others' humorous entertainment. I used a leftover hole in the distributor and threaded a small screw in the side, to "pin" the rotating plate from rotating, for the drive home. My timing stayed consistent, and I have since applied a couple of mini tack welds to the assembly, while disassembling and lubricating everything inside.

Order has been restored to the universe... while I await the rebuild of another distributor by a specialist, which will replace this clackity and tired old unit.

A Special debt of gratitude and appreciation for the 2002 tribe that helped me with all the prep work and machine shop services, while in Chicago. The 2002 people are some of the BEST people....and when you're the idiot.... sometimes it DOES take a village!

Until next time - if you see an obnoxious gray 2002 blasting down the highway - say HELLO - and then go home and hug your cylinder head.

I like to call myself a permanoob. Always learning. ;)